In 1990, TSUNTIEN focused on development and production of the high performance reducer.

IN 1991 , released the innovative revolution-rotation roller drive mechanism into reducer , which is the prototype of Roladrive reducer .The Roladrive reducer was applied successfully to the machine required high torque and heavy duty .

In 1994 , awarded Gold medal of iNEA , Nuremberg Germany

In 2011, TSUNTIEN entered the high precision reducer industry accompanied more than 20-years sophisticated experience of Roladrive reducer technique.

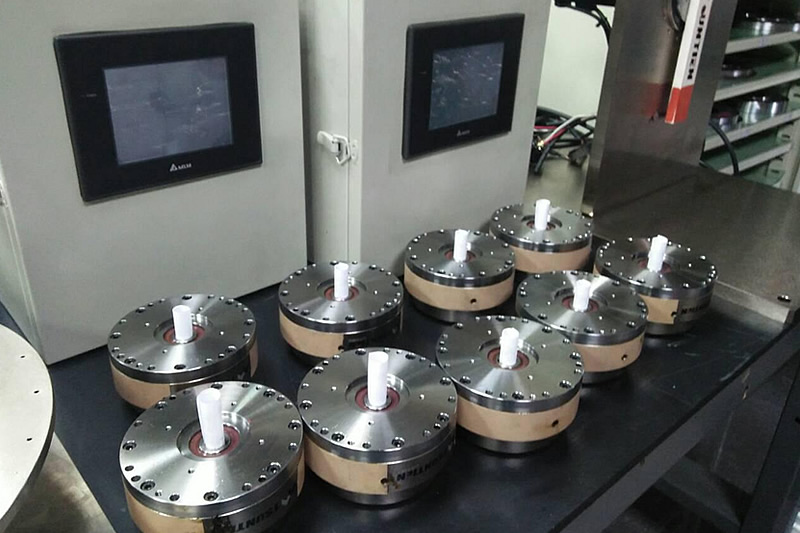

In 2012 , purchased high precision tooling machine , 3D CMM and precision / noise / vibration inspection equipment gradually , ensure our mass-production capability and quality stability to meet customer stricter and stricter demands.

In 2013 , TSUNTIEN product successfully sold to the rotary table / position device , ATC , tool magazine , tube-bending machine , chemical engineering ,spring / screw / nut machine , automation , electronic wafer / inspection equipment , SCARA , high precision 4 axle / 6 axle robotic arm and related 7th and 8th axis application industry and won the good reputation.

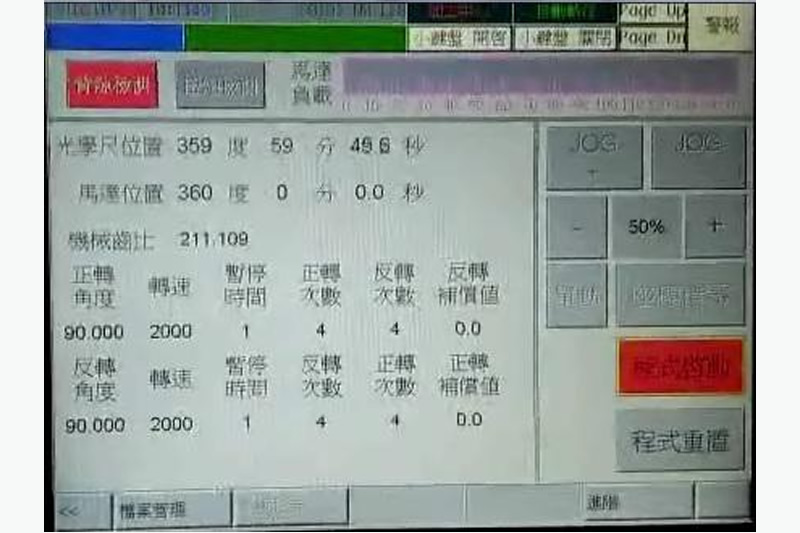

In 2016 ,purchased U. K.RENISHAW angle-analysis device for precision inspection and recruit the members of QC department to fulfill all-inspection strategy

In 2017 , establish global marketing channel for sustainable development , cooperate with oversea agencies closely , promote TSUNTIEN/KOTEC to global market.

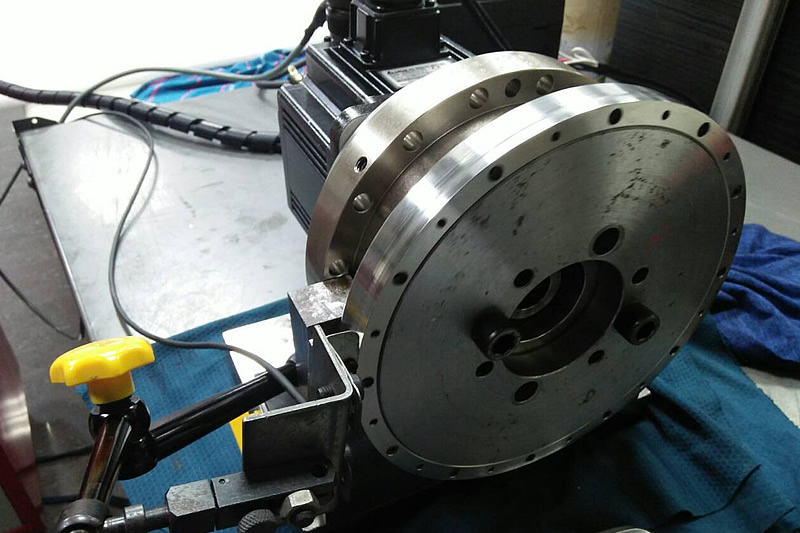

In order to satisfying the mainstream of automatic robotic industry , TSUNTIEN proceeded to develop the heavier and bigger reducers at the beginning , then gradually toward to more compact and lighter reducer for space-saving requirement of automatic robotic industry , which could lighten the weight of body of robotic arm , and eliminate the phenomenon of high inertia ratio meantime.

TSUNTIEN also released specific reducers via simple installation , direct drive with precise position , especially be proper to applied to positioner , turret and ATC industries.

With all roller-gears contact simultaneous , therefore the transmission of and power and torque are high precise and efficient . As a result , the mechanism loss is lower.

Unique roller-gear structure makes lower noise than conventional reducer and obtain higher output torque . The reducer provide near zero backlash , the ability to support heavy external loads and has significant advantage in terms of ease-of-use and low cost for performance.

TSUNTIEN precision co., LTD had expandable production capacity , owned 3000 square meter modernized factory , the crucial process equipment , such as CNC machining center , milling machine , gear-shaping machine , gear-grinding machine with flexible shift work . Overall inspection equipment such as teeth-profile equipment , CMM , Noise & vibration measuring machine and so on . Cooperated with long-term & reliable outsourcing suppliers, could meet any unpredictable mass orders and also ensure the premium quality meantime.